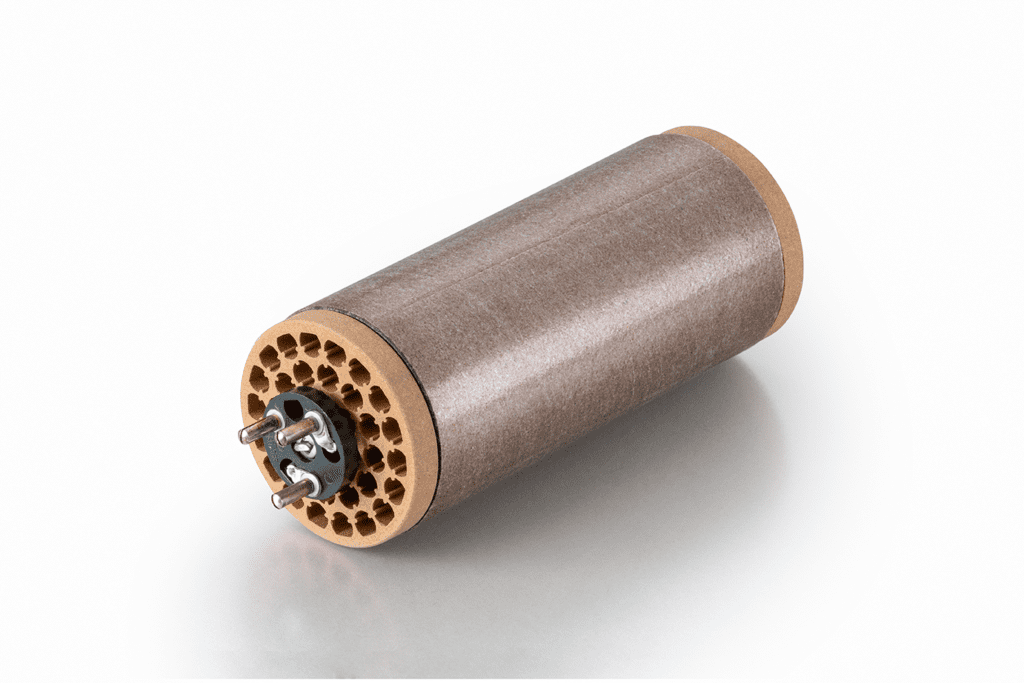

Industrial Hot Air Device Type 5000

Highlights

Heavy-duty air heater for continuous use

Integration into professional production processes

Available in a wide range of performance variants

High performance in a compact industrial air heater

Description

The industrial air heater type 5000 continuously produces hot air at a constant temperature. The compact and lightweight air heater enables integration into professional production processes despite its high hot air output.

The air heater type 5000 has numerous different applications. The air heaters are utilised in machines and on conveyor belts among other places. Here, activation, shrinkage, drying, and forming are accomplished through the use of hot air.

The air heaters can be switched between 3 stages and can be equipped with different heating capacities of 230 V or 400 V 3-phase AC up to a maximum of 650 °C. A side channel compressor, blower, or compressor is required for Type 5000. Depending on the nozzle, the required air volume is between 500 and 1500 litres/min. Individual solutions can be achieved by altering and concentrating the air flow with various attachable nozzles.

Technical specifications

Voltage:

230 V - 400 V

Frequency range:

50Hz - 60Hz

Power:

3000W - 7500W

Air flow:

500 - 1500 I/min

Max. air pressure:

1 bar

Max. temperature:

700°C

Max. ambient temperature:

65°C

Min. supply air temperature:

0°C

Max. supply air temperature:

65°C

Noise emission level:

< 70dB

Protection class:

I /

Weight:

1,400 kg

Accessories

- Nozzles

- Heating elements

Item no. 4021

Wide slot nozzle 150 x 1 mm

Item no. 4022

Wide slot nozzle 150 x 10 mm

Item no. 4030

Item no. 4031

Item no. 3108

Heating element 230V 2200+2800W

Item no. 3112

Heating element 400V 3X1700W

Item no. 3117

Heating element 400V 3x2500W

Item no. 3109

Heating element 230V 3x1000W

Item no. 3114

Heating element 230V 3x2000W

Item no. 3110

Heating element 400V 3x1000W

Item no. 3115

Heating element 400V 3x2000W

Item no. 3111

Heating element 230V 3x1700W

Item no. 3116

Heating element 230V 3x2500W

Application areas

Packaging industry

Mechanical engineering

Conveyor belt technology and assembly line technology

Drying process

Pharmaceutical industry

Sterilization process

Food industry

Foil shrinking

Wine and spirits bottling plants

Coating process

Laminating process