Quick-S-electronic

Highlights

Welding without fatigue due to the ergonomic handle shape

Own powerful air supply

Constant welding power

Easy to change carbon brushes

Description

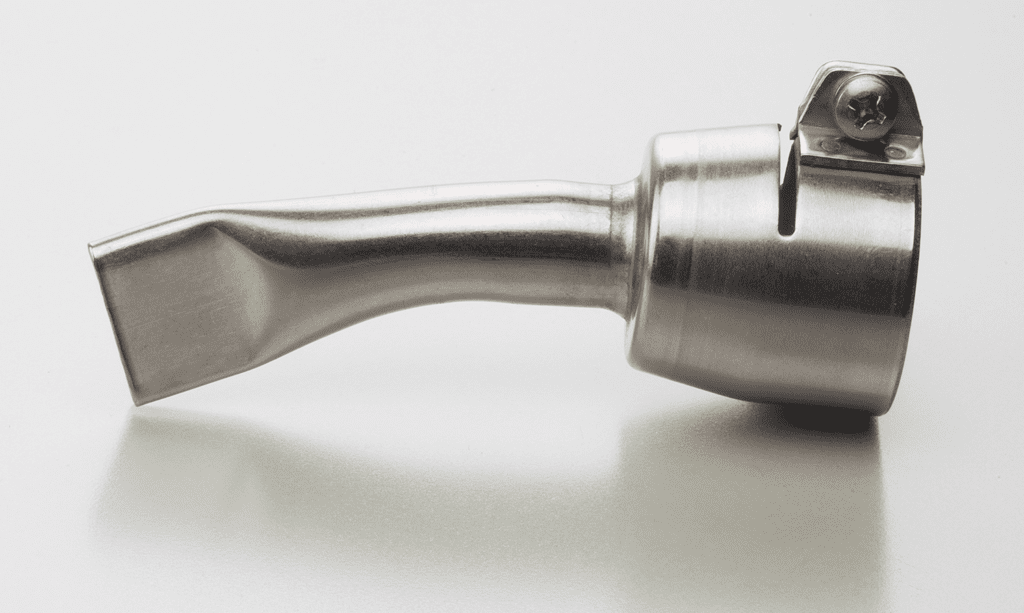

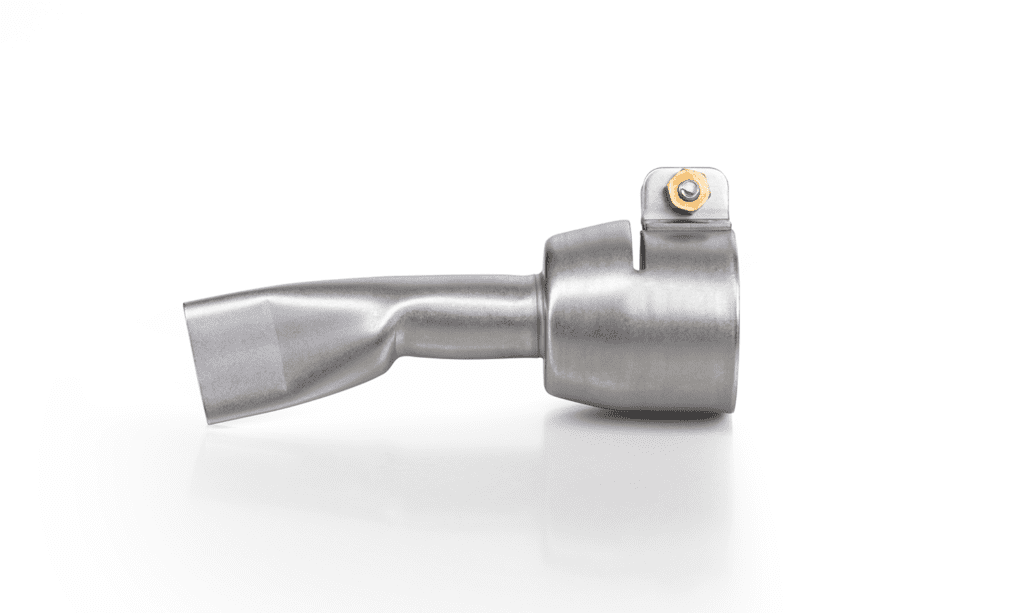

The Quick-S-electronic hot air welder is distinguished by its one-of-a-kind ergonomic handle, which was designed by an industrial designer. The tool enables professional and fatigue-free welding due to its portability and light weight.

The appliance features constant and completely dependable control electronics for temperatures up to 700 °C and a heating power of 1500W 230V or up to 1650W 120V.

Due to the availability of a wide range of nozzles and other accessories, the Quick-S-electronic unit is incredibly adaptable

The Quick-S hand welder is ideal for professional use in the pool area or on construction sites. For flexible thermoplastic welding, it is equally suitable for tradespeople like roofers, floor installers, tarpaulin manufacturers, and plastics processors.

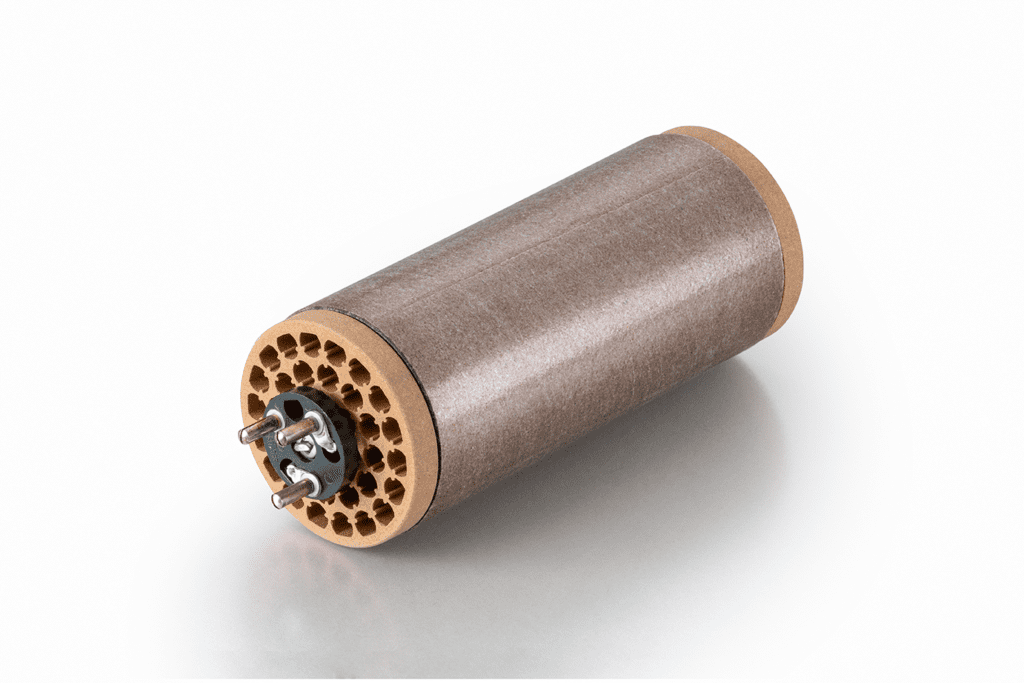

Additionally, the device is easy to maintain and only needs the carbon brushes to be changed after 1,500 hours. After the carbon brushes are used up, the carbon brushes have a cut-off mechanism to keep the motor from being damaged. The carbon brushes can be changed several times. Without opening the device, the carbon can be easily replaced from the outside.

Technical specifications

Voltage:

230V; 120V

Power:

max. 1600W

Frequency:

50/60 Hz

Temperature:

20 - 700°C

Air flow:

240 l/min

Dimensions:

Ø 360 x 95 mm, handle Ø 76 mm

Weight:

1.2 kg with 3m connecting cable

Conformity mark

CE; EAC

Protection class:

II /

Accessories

- Nozzles

- Speed welding nozzles

- Pressure rollers

- General Accessories

- Tool case

- Heating elements

Item no. 4000

Tubular nozzle 5mm

Item no. 4002.90

Angle nozzle 20mm, 90° push-fit

Item no. 4005

Tubular nozzle 15mm

Item no. 4060

Wide slot nozzle 60mm

Item no. 4002

Wide slot nozzle 20mm

Item no. 4003

Wide slot nozzle 40mm

Item no. 4007

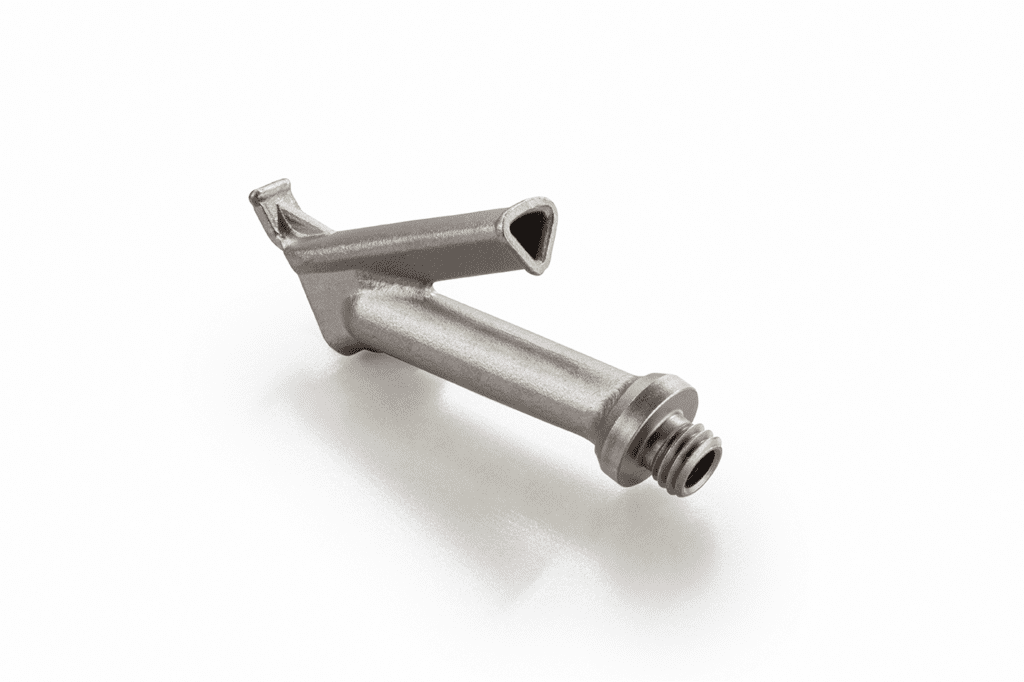

Nozzle Adapter for M10 screw-fit nozzles

Item no. 4090

Wide slot nozzle 90mm

Item no. 4002.15

Angle nozzle 20mm, 15° push-fit

Item no. 4003.60

Angle nozzle 40mm, 60° push-fit

Item no. 4008

Nozzle Adapter for M14 screw-fit nozzles

Item no. 5016

Spoon reflector

Item no. 4002.60

Angle nozzle 20mm, 60° push-fit

Item no. 4004

Wide slot perforated nozzle 40mm

Item no. 4000.V

5mm tubular elongated 150mm nozzle

Item no. 9701

Tubular nozzle 5mm, re-inforced

Item no. 5000

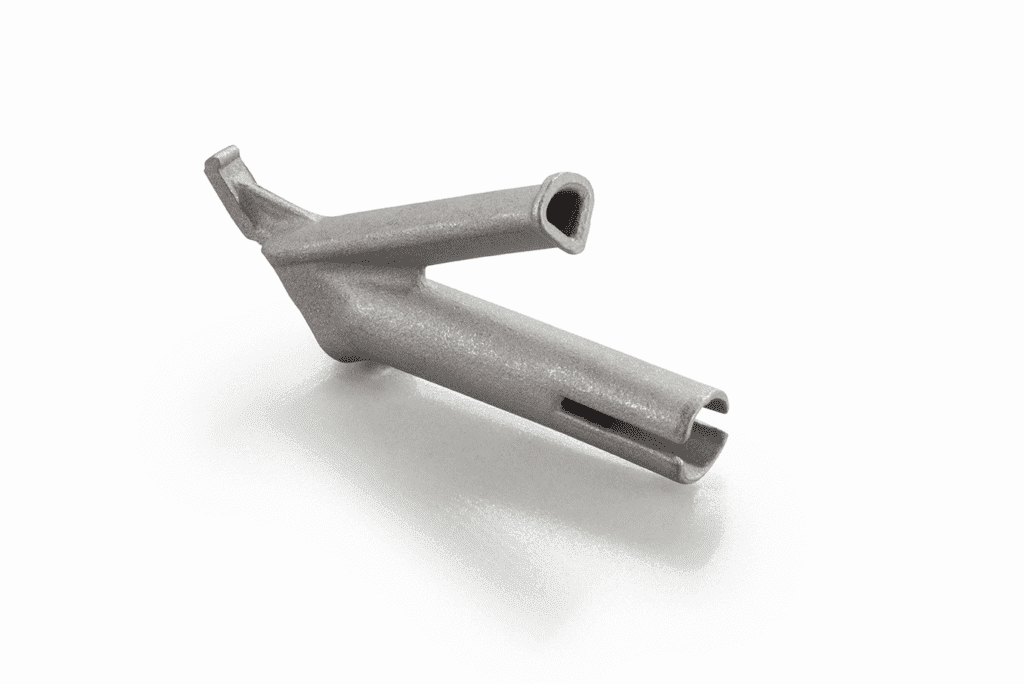

5.7mm triangular speed weld nozzle (for nozzle 4000)

Item no. 5012

5mm round speed weld nozzle (for nozzle 4000)

Item no. 5015

Tacking jet (for nozzle 4000)

Item no. 5002

5.7mm triangular speed weld nozzle (for nozzle 4007)

Item no. 5006

4mm round speed weld nozzle (for nozzle 4007)

Item no. 5017

Tacking jet curved (for nozzle 4007)

Item no. 5001

7mm triangular speed weld nozzle (for nozzle 4000)

Item no. 5013

5mm triangular speed weld nozzle (for nozzle 4000)

Item no. 5003

7mm triangular speed weld nozzle (for nozzle 4007)

Item no. 5007

5mm round speed weld nozzle (for nozzle 4007)

Item no. 5010

3mm round speed weld nozzle (for nozzle 4000)

Item no. 5014

7.5mm triangular speed weld nozzle (for nozzle 4000)

Item no. 5004

Tacking jet (for nozzle 4007)

Item no. 5008

5mm triangular speed weld nozzle (for nozzle 4007)

Item no. 5011

4mm round speed weld nozzle (for nozzle 4000)

Item no. 5022

5mm round speed weld nozzle for polyolefin (for nozzle 4000)

Item no. 5005

3mm round speed weld nozzle (for nozzle 4007)

Item no. 5009

7.5mm triangular speed weld nozzle (for nozzle 4007)

Item no. 6991

28mm PTFE pressure roller with ball bearings

Item no. 6995

45mm 45° silicone pressure roller with ball bearings

Item no. 7000

45mm silicone pressure roller, double arm

Item no. 7006

45mm 45° silicone pressure roller

Item no. 6992

45mm PTFE pressure roller with ball bearings

Item no. 6996

80mm silicone pressure roller with ball bearings

Item no. 7001

45mm silicone pressure roller, single arm

Item no. 7007

Pressure roller for custom seal 7mm

Item no. 6993

Brass penny roller 30mm

Item no. 6997

45mm silicone pressure roller with ball bearings, single arm

Item no. 7002

80mm silicone pressure roller

Item no. 7009

Pressure roller for custom seal 9mm

Item no. 6994

28mm silicone pressure roller with ball bearings

Item no. 6998

45mm silicone pressure roller with ball bearings, double arm

Item no. 7005

5mm welding rod pressure roller

Item no. 5021

Trimming guide

Item no. 7018

Trimming knife

Item no. 7010

Cutter

Item no. 7020

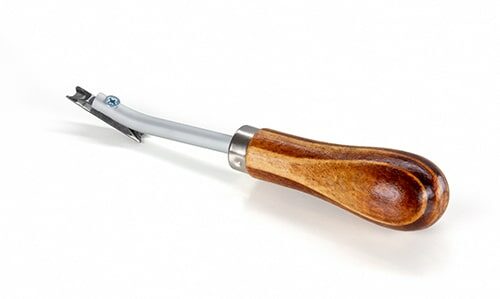

Seam trimmer

Item no. 7011

Hand groover

Item no. 7026

Brass cleaning brush for speed weld nozzles 3-5mm

Item no. 7014

Seam probe tester

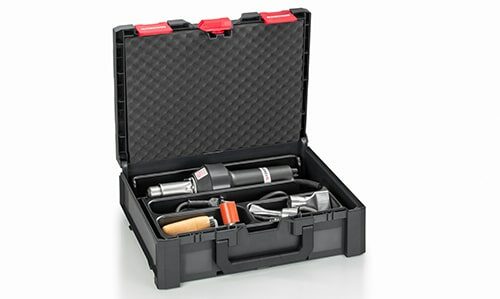

Item no. 7025

Tool case

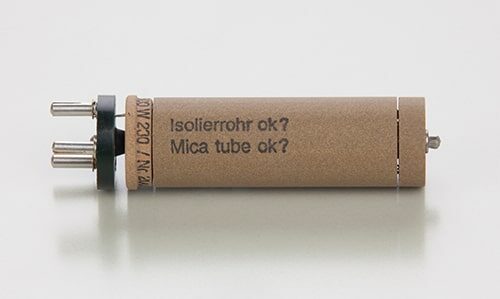

Item no. 2007

Heating element 230V 1500W

Item no. 2011

Heating element 120V 1600W

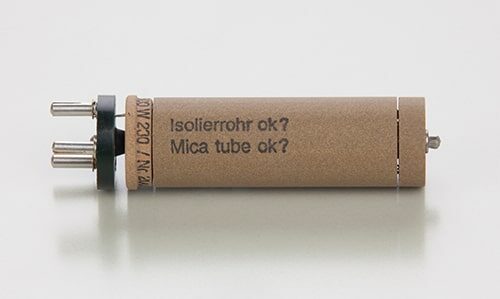

Item no. 4011

Insulating sleeve

Item no. 2008

Heating element 120V 1300W

Item no. 2009

Heating element 230V 1650W

Application areas

Advertising banner welding and tarpaulin welding

Processing of PVC floor coverings and linoleum

Repair of car tarpaulins, tents and plastic

Shrinking of foils, molded parts and cables

Separating and merging of synthetic threads and fabrics

Forming of plastic and thermoplastic semi-finished products

Processing of all thermoplastic hard materials in plastic construction and container construction

Sterilizing packaging materials or used in food processing

Removal of plastic press burrs and shine of plastic surfaces

Use in electromechanical work

Flat roof membrane welding

Shrinking of hoses, packaging films

Construction and repair of aquaculture and boats

Sealing pools and ponds

Smoothing pills and dragees