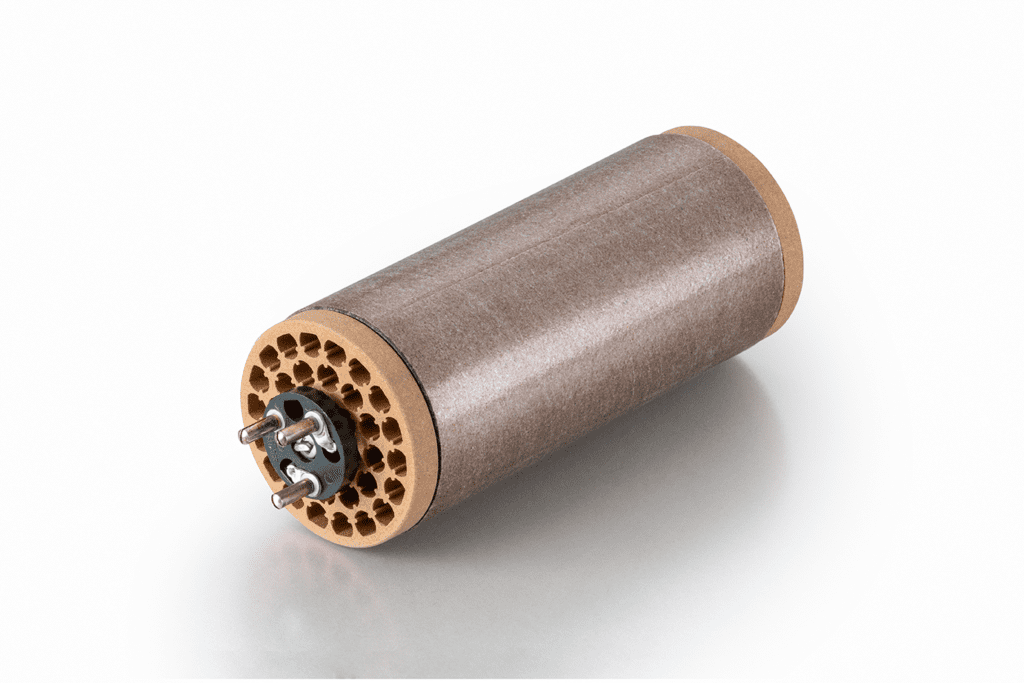

Grand-L-electronic

Highlights

Powerful hot air blower up to 3400 W

Robust and construction site suitable heat gun

Strong air volume of 300 litres/minute

Ideal for heating, shrinking and drying

description

The Grand-L-electronic hot air blower is used wherever hot air flows are required for the purpose of heating, warming up, deforming, shrinking and activating.

The heating power of either 3000 W or 3400 W 230 V is infinitely variable from 20 °C to 700 °C. The device features new and very reliable temperature control electronics. Depending on the nozzle, the air output can reach up to 300 litres/min. The air flow can be altered through various attachable nozzles, allowing for a wide range of applications.

In addition, the device has a cold stage without having to adjust the heating preselection. The collector brushes of the motor can be changed several times and thus enable continuous operation of the device. The carbon brushes can be easily changed from the outside without opening the appliance. and only need to be replaced after around 1,500 hours. The carbon brushes of our hand welders are equipped with a switch-off mechanism which prevents damage to the motor after the carbon brushes have been used up.

The Grand-L-electronic can be ordered with either a 20mm or 50mm basic nozzle.

Technical specifications

Power:

3000W 230V; 3400W 230V; 2200W 120V

Frequency range:

50/60Hz

Temperature:

20-700 °C, infinitely adjustable

Dimensions:

Ø 340 x 95 mm, handle Ø 48 mm

Weight:

1,65 kg with 3m connecting cable

Conformity mark

CE; EAC

Protection class:

II /  (Double insulated)

(Double insulated)

Accessories

- Nozzles

- Tool case

- Heating elements

Item no. 4021

Item no. 4032

Wide slot nozzle 75 x 2 mm [only for version without heat protection]

Item no. 4022

Item no. 4030

Item no. 4031

Item no. 7025

Item no. 3064

Heating element 230V 3000W

Item no. 3065

Heating element 230V 3400W

Item no. 3066

Heating element 120V 2200W

Application areas

Installation in machines and on conveyor belts

Use in electromechanical work

Repair of plastic parts on automobiles and motorcycles

Shrinkage of heat-shrinkable hoses and packaging foils

Heating for forming thermoplastic semi-finished products

Drying of water-moist surfaces

Forming and sealing of blister packs

Deformation and machining of prostheses

Thawing of frozen water pipes

Removal of paints and varnish

Activating and releasing solvent-free adhesives and hot-melt adhesives

All types of drying and heating processes

Shrinkage of packaging films and moulded parts

Separating and merging of synthetic threads and fabrics

Sterilization of packaging materials

Removal of plastic press burrs and shine of plastic surfaces